source:本站author:超級管理員time:2025-02-26views:548857

Does plasma cleaning equipment play a crucial role in wafer/semiconductor packaging? Do you want to know the impact of plasma cleaning on semiconductor manufacturing?

In the semiconductor manufacturing process, plasma cleaning treatment is a key technology. Today, please follow the editor to learn more. Below is a detailed introduction: So, please read this article carefully because it contains almost all the answers to the questions you may ask, including the meaning, effect, process flow, and functions of vacuum plasma cleaning machine?

A vacuum plasma cleaning machine is a material state composed of various active particles such as ions, electrons, and free radicals, with reaction gases (such as oxygen, argon, hydrogen, etc.). The commonly used plasma cleaning gas, oxygen (O ?), is used to remove organic pollutants and photoresist. Argon (Ar): Used for physical cleaning to remove particulate pollutants. Nitrogen (N ?): used for surface activation and passivation treatment.

Plasma is formed in the vacuum chamber through devices such as RF power supply during the vacuum plasma cleaning process. The active particles in this type of plasma have high energy and undergo physical or chemical reactions with pollutants on the wafer surface.

Plasma cleaning equipment mainly uses ion bombardment. Under the action of an electric field, ions in the plasma accelerate and collide with the surface of the wafer, which can remove surface pollutants such as metal impurities and organic matter, thus achieving the purpose of cleaning.

Vacuum plasma cleaning technology can chemically react active particles with pollutants, convert them into volatile substances, and then extract the chamber through a vacuum pump. For example, oxygen plasma can undergo oxidation reactions with organic compounds, producing volatile substances such as carbon dioxide and water.

Semiconductors processed by vacuum plasma cleaning machines have the following effects:

1. Plasma cleaning technology can effectively remove various small pollutants on the surface of wafers, ensuring a high level of cleanliness on the wafer surface. This is beneficial for subsequent processes such as photolithography and etching, and increases the yield of chip manufacturing.

2. Plasma cleaning is a dry cleaning technique that, compared to some traditional wet chemical cleaning methods, avoids problems such as corrosion and scratches on the wafer surface caused by the use of chemical reagents, and has a relatively small impact on the physical and chemical properties of the wafer. It is particularly suitable for advanced semiconductor processes that require extremely high surface quality.

3. In the vacuum chamber, the vacuum plasma cleaning machine can be evenly distributed to clean the wafer surface uniformly, ensuring consistent cleaning effect on the entire wafer surface. This is very important for ensuring the consistency of chip performance in large-scale integrated circuit manufacturing.

4. In the process of vacuum plasma cleaning, there is no need to use a large amount of chemical reagents, which reduces the discharge of chemical waste and is more environmentally friendly. Compared with some wet cleaning processes, plasma cleaning machines also have certain advantages in energy consumption and water resource consumption.

How are wafers, chips, and semiconductors processed in vacuum plasma cleaning machines

Firstly, wafer mounting: Place the wafer to be cleaned into the vacuum chamber of the plasma cleaning equipment, usually using special wafer fixtures to secure the wafer and ensure its stability during the cleaning process.

Secondly, vacuum pumping: Start the vacuum pump to extract the indoor air and achieve a certain degree of vacuum, which can create conditions for the subsequent formation of stable plasma.

Finally, gas introduction: The gas flow rate and pressure are precisely controlled through a gas flow control system, and an appropriate amount of reaction gas, such as oxygen, argon, hydrogen, or a mixture of gases, is introduced into the chamber for precise control according to cleaning requirements.

Plasma generation: Turn on the RF power supply, generate a high-frequency electric field inside the cavity, ionize the reaction gas to form plasma, and physically and chemically react with the pollutants on the wafer surface for cleaning. The cleaning time is generally between a few minutes to several tens of minutes, depending on the degree of wafer contamination and cleaning process requirements. Post cleaning treatment: After cleaning, turn off the RF power and gas supply, stop plasma generation, and then extract the exhaust gas from the chamber through a vacuum pump. Finally, remove the wafer from the chamber for subsequent testing or processing.

What are the crucial roles that vacuum plasma cleaning machines play in the field of wafers!

1. Pre lithography cleaning: The vacuum plasma cleaning machine can remove residual photoresist and organic contamination on the wafer surface, ensuring that the photoresist can evenly coat the wafer surface and improve the accuracy and quality of lithography patterns.

2. After etching cleaning: After plasma etching process, etching residues and polymers on the wafer surface can be quickly removed, restoring the cleanliness of the wafer surface and preparing for subsequent processes such as metal deposition and interconnection.

3. Pre bonding cleaning: Cleaning the wafer surface before the chip bonding process can improve surface flatness and cleanliness, enhance bonding reliability and stability, and ensure good electrical and mechanical connections between chips.

Almost all manufacturers in the semiconductor industry use plasma cleaning machines, indicating their increasing importance,

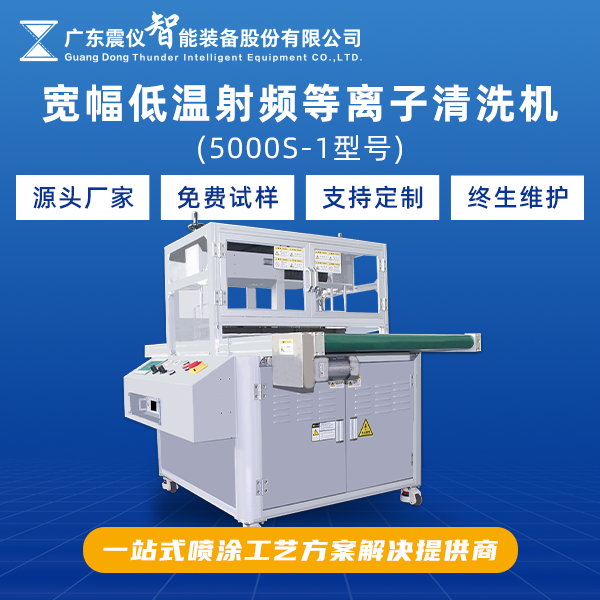

Nowadays, plasma cleaning machines are widely used in the semiconductor field. Due to their high efficiency, accuracy, and pollution-free characteristics, vacuum plasma cleaning machines play an important role in the semiconductor manufacturing process. Currently, Zhenyi Co., Ltd. focuses on the research and development of cleaning surface treatment

technology, which can carry multiple nozzles for cleaning, activation, and modification treatment. Not only can plasma cleaning machines effectively remove small particle pollutants on the wafer surface to meet the high cleanliness requirements of semiconductor manufacturing, but they can also be used to clean and activate the substrate surface during chip packaging to ensure good bonding effect.

2024-11

Dry ultrasonic cleaning machine (USC) is an efficient,···

2021-09

Smart phones are now more and more widely used in life···

2024-12

Plasma cleaning machine, a secret weapon that can quic···

2025-01

Why is a plasma cleaning machine used before packaging···

2024-12

With the continuous advancement of science and technol···