source:Thunder Corporationauthor:rogentime:2023-04-20views:6626

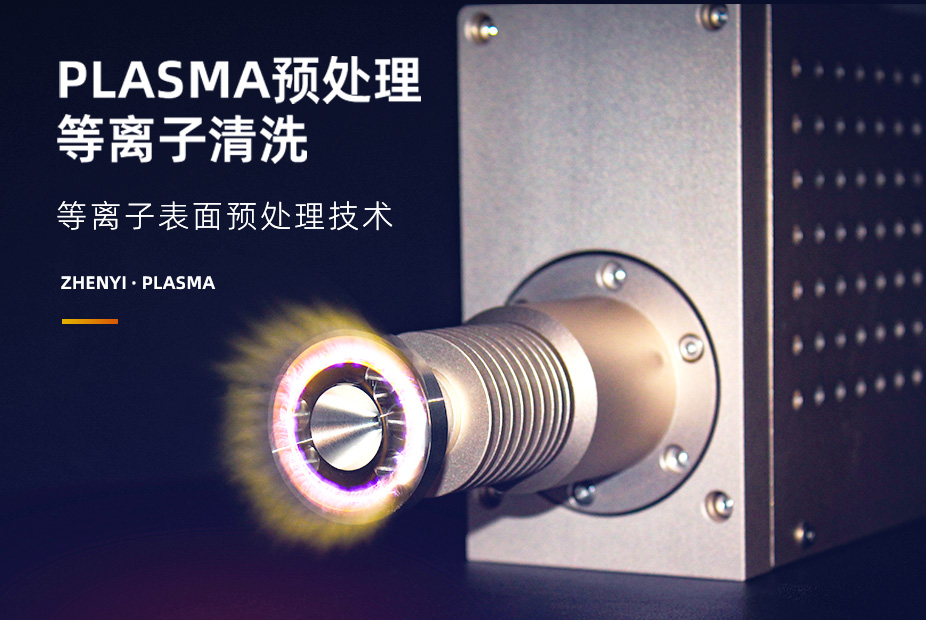

With the increasing demand for environmental protection and energy efficiency, the future development trend of the automotive manufacturing industry will focus on material and structural innovation. Lightweight materials such as carbon fiber, aluminum, and magnesium have already been widely used to reduce vehicle weight and improve kinetic energy efficiency. In addition, plasma surface pretreatment technology is also receiving more attention from automotive manufacturers because it can effectively improve the bonding performance of composite materials, creating stronger, lighter, corrosion-resistant, and wear-resistant structures.

In addition to the application of lightweight materials, plasma surface pretreatment technology is becoming increasingly important in the automotive industry. Plasma surface pretreatment technology is a method of using plasma to clean the surface. This process can effectively improve the bonding performance of new composite materials.

Plasma surface pretreatment technology is particularly suitable for bonding different materials, which may be difficult with traditional methods. By using plasma surface pretreatment technology, manufacturers can create structures with high strength, light weight, corrosion resistance, and wear resistance.

Overall, lightweight materials and plasma surface pretreatment technology are expected to lead the innovation of the automotive industry in the coming years. By reducing vehicle weight and improving durability, these new technologies will help improve fuel efficiency, reduce emissions, and make vehicles more sustainable and environmentally friendly.

Plasma surface pretreatment technology is a technique that utilizes plasma to generate chemical reactions or physical effects on surfaces, which can improve adhesion, wetting, and reactivity, thereby enhancing material performance. In addition to the automotive manufacturing industry, plasma surface pretreatment technology also has a wide range of applications in fields such as electronics, aerospace, medical, and environmental protection.

In the field of electronics, plasma surface pretreatment technology can be used in the manufacturing and packaging of semiconductor devices. By forming an oxide or nitride layer on the chip surface, the quality and stability of the chip can be improved. In the manufacture of optical devices, plasma surface pretreatment technology can be used for coatings and surface modification to improve transparency and wear resistance.

In the aerospace field, plasma surface pretreatment technology can be used for surface treatment and coating of metal materials. Through plasma deposition technology, a uniform coating can be formed on the metal surface, improving material corrosion resistance and wear resistance. In spacecraft manufacturing, plasma surface pretreatment technology can also be used for cleaning and disinfection to improve material reliability and durability.

In the medical field, plasma surface pretreatment technology can be used for surface treatment of artificial joints and medical devices. By forming nanostructures or chemical reaction products on the surface, the biocompatibility and corrosion resistance of the material can be improved, reducing infections and rejection reactions.

In the field of environmental protection, plasma surface pretreatment technology can be used for wastewater treatment and air purification. Through plasma oxidation and reduction reactions, pollutants can be converted into harmless substances or captured and decomposed harmful gases.

In summary, plasma surface pretreatment technology has a wide range of applications, improving material performance, product quality, and reliability, while also reducing environmental pollution and energy consumption. With continuous technological development, plasma surface pretreatment technology will become an important tool in materials science and industrial manufacturing.

2021-10

Glass coating deposition, can help in the case of cost···

2021-09

Nowadays, the demand for anti-fingerprint is more and ···

2022-05

In the daily plasma cleaning process of the plasma cle···

2024-11

Coating is the main process of post printing processin···

2025-03

Fluorine free fingerprint oil anti fouling coating: a ···