source:Thunder Corporationauthor:Rogentime:2023-05-16views:6936

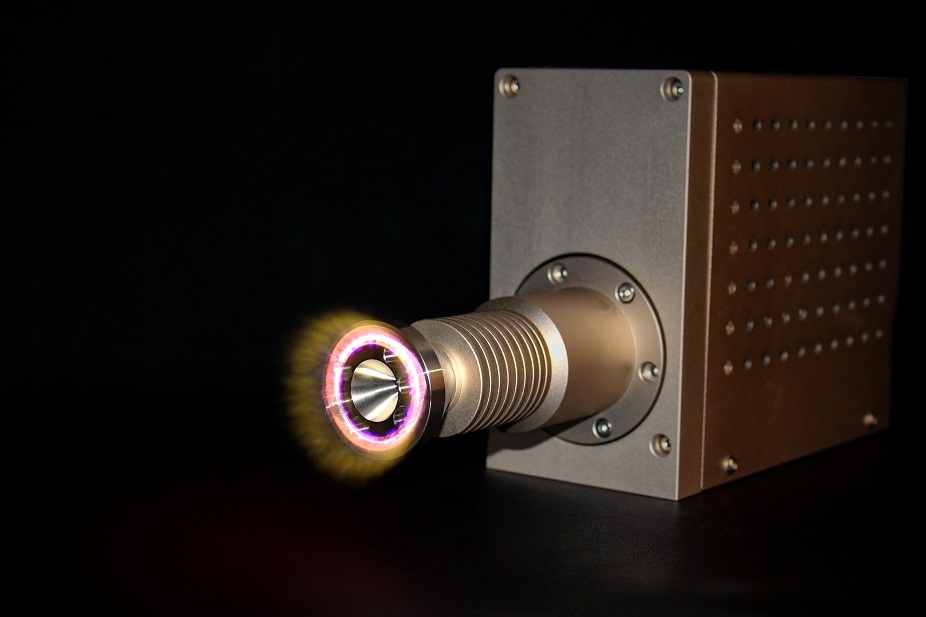

Plasma cleaning machines are devices that utilize plasma, including plasma beams and plasma jets, to clean and modify material surfaces. The plasma parameters have a significant impact on the cleaning efficiency and surface modification. Here are some key parameters and their effects:

1、Plasma Density: Plasma density refers to the concentration of plasma in the system. Higher plasma density usually enhances the cleaning efficiency and the rate of surface modification because more active particles can react with the material surface. However, excessively high plasma density may lead to surface over-etching and damage.

2、Plasma Energy: Plasma energy refers to the energy level of the plasma particles. Higher energy levels typically improve cleaning efficiency and the speed of surface modification since higher-energy plasma particles can more easily penetrate surface layers and interact with the material. Nevertheless, excessively high energy can cause surface damage.

3、Plasma Composition: Plasma composition refers to the different types of ions and chemical species present in the plasma. Different plasma compositions yield varying cleaning and surface modification effects. For example, oxygen plasma provides oxidation and cleaning capabilities, while nitrogen plasma offers nitriding and hardening abilities. Selecting the appropriate plasma composition can achieve the desired cleaning and surface modification effects.

4、Plasma Flow Rate and Jet Velocity: Plasma flow rate and jet velocity refer to the speed at which plasma enters the cleaning chamber or contacts the material surface. Higher flow rates and velocities generally improve cleaning efficiency and the rate of surface modification because more plasma interacts with the material surface. However, excessively high flow rates and velocities may result in energy dispersion and excessive heating of the material.

In summary, the selection of plasma parameters in a plasma cleaning machine requires considering cleaning efficiency, surface modification effects, and material tolerance. Depending on specific cleaning requirements and material characteristics, adjusting plasma parameters can achieve optimal cleaning and surface modification effects. Besides plasma parameters, other factors also influence cleaning efficiency and surface modification:

1、Cleaning Time: Cleaning time refers to the duration of material exposure to plasma treatment. Longer cleaning times usually increase the extent of cleaning efficiency and surface modification since more time allows for sufficient interaction between the plasma and material surface. However, excessively long cleaning times may cause over-etching or material damage.

2、Cleaning Atmosphere: Cleaning atmosphere refers to the gas environment within the cleaning chamber, which can be inert gas (such as nitrogen) or reactive gas (such as oxygen). Different cleaning atmospheres have varying effects on cleaning efficiency and surface modification. For example, plasma cleaning in an inert atmosphere can reduce oxidation reactions, while plasma cleaning in a reactive atmosphere can enhance oxidation reactions.

3、Material Properties: Different materials possess distinct chemical and physical properties, leading to varied responses to plasma cleaning. For instance, metal materials may be more sensitive to oxygen plasma cleaning, while polymer materials may be more responsive to nitrogen plasma cleaning. Understanding the material characteristics aids in selecting appropriate cleaning parameters.

4、Surface Topography: The surface morphology of the material, including roughness and surface defects, affects the contact and reaction between plasma and the material surface. Surfaces with larger areas and higher roughness may require longer treatment times or higher-energy plasma for thorough cleaning and modification.

5、Pre-Cleaning Preparation: Prior to plasma cleaning, material pre-treatment is often necessary, such as removing oils and activating the surface. Proper pre-cleaning preparation enhances cleaning efficiency and surface modification effects.

In conclusion, the plasma parameters in a plasma cleaning machine, along with other relevant factors, collectively impact cleaning efficiency and surface modification. Experimental investigation and optimization are required to determine the best parameters and conditions based on specific applications and materials.

2021-09

As a key material for folding screen mobile phones, th···

2017-05

How are silicone rubber based on the mechanism of vulc···

2021-08

With the opening of the global new energy market, coun···

2023-04

The construction of an automated production line with ···

2021-10

With the continuous development of plasma spraying coa···